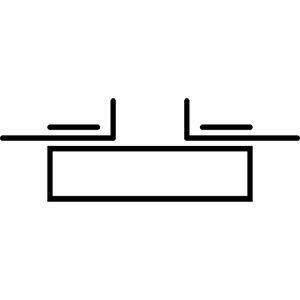

To prevent warpage, sink marks and unsightly surfaces, some fundamental principles of plastic part design are adhered to. Ribs can serve as a fitting example in this context. Not only do they enhance the robustness of a part, but also act as a defence against its distortion. The so-called box incidence is a common trait of box-shaped parts devoid of ribs. In this process, the outer walls bend inwards in a semicircular shape, as the stresses caused by the cooling of the part are not absorbed by the ribs.

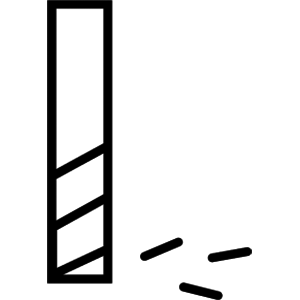

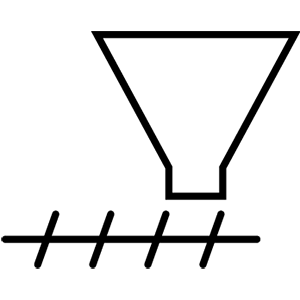

The inserted ribs, in turn, should not exceed 60% of the total wall thickness, as this could potentially result in unsightly sink marks on the shared surface.

We diligently adhere to these and many other design norms right from the quotation phase, and are more than happy to assist you. Upon request, we also perform mould flow analyses. The injection point can be simulated to verify the filling of the geometry and determine potential distortion.